4 min read

Hitachi ABB Power Grids launches path-breaking traction transformers for sustainable mobility

As global leaders in traction transformers with more than 100 years of experience, Hitachi ABB Power Grids has been successfully pushing the envelope of technological leadership by bringing new technologies that address challenges like space and weight limitations, maintenance, and energy efficiency.

Today, 1 out every 3 AC trains in the world have traction transformers by Hitachi ABB Power Grids installed and more than 30,000 units of such transformers are in operation across the world.

Rail transport is the most energy efficient mode of transport, and its future growth demands even more efficient and reliable traction transformer solutions.

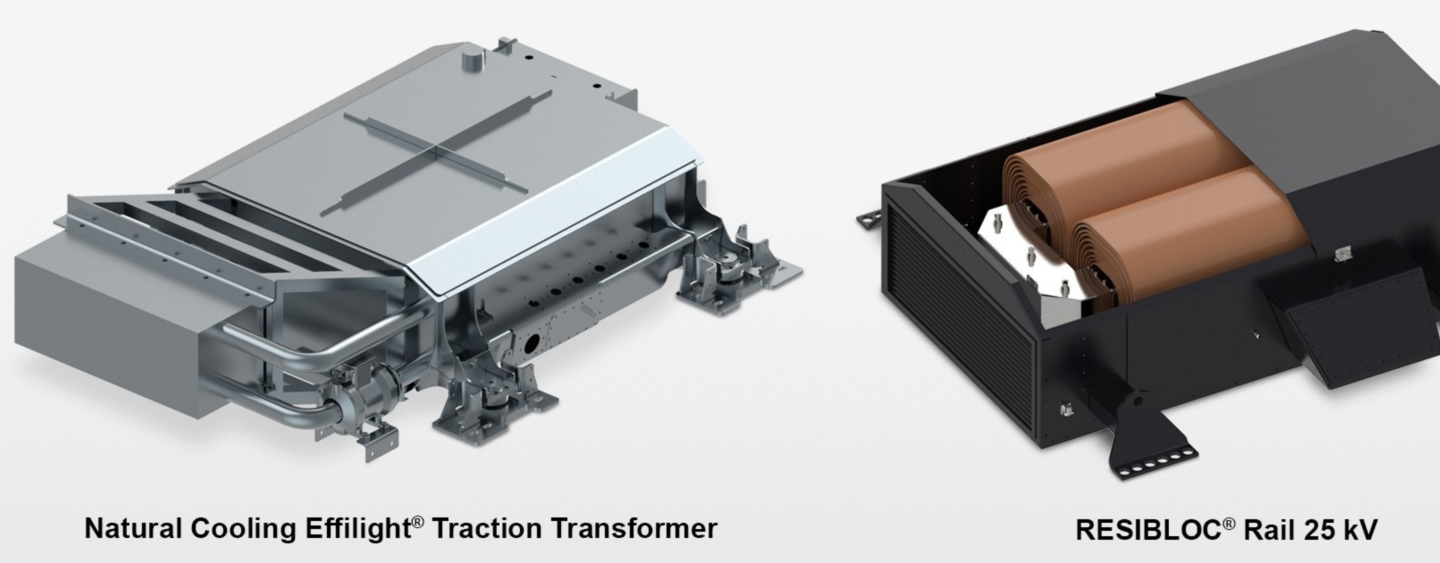

Hitachi ABB Power Grids has introduced two new traction transformers that help customers reduce overall costs while improving efficiency and reliability: RESIBLOC® CRail 25 kV & Natural Cooling Effilight® Traction Transformer.

“We are immensely pleased to bring these two solutions to our customers in the rail industry. Both the products have been designed on our existing proven & successful platforms i.e., RESIBLOC® for dry and Effilight® for liquid-filled traction transformers, said Stephane Schaal, Head of Global Traction and Distribution Transformer Product Groups, Hitachi ABB Power Grids, “these will bring new, additional value that will help our customers reduce operating costs and improve reliability”

Natural Cooling Effilight® Traction Transformer (NCETT)

Due to their compact size, conventional traction transformers are subject to substantial energy losses which heat-up the internal windings. This requires an external 'cooling-system' with a heat exchanger and motorized ‘air-fans’ - adding to maintenance and energy consumption for train operators.

Natural Cooling Effilight® Traction Transformer (NCETT) replaces the traditional fan-based cooling system with natural and sustainable alternative – natural airflow of the train’s motion.

The NCETT uses a specially designed cooling-system that utilizes the natural air flow caused by the train’s motion and directs it to the heat exchangers, thereby eliminating the need for motorized air-fans.

The removal of air-fan based cooling system reduces the overall costs incurred on energy consumption and maintenance of the cooling system by train operators. The elimination of fan-based cooling system reduces risk of failure and improves reliability by 20% with no downtime for the fans, motors, and their supply system.

The NCETT also retains the benefits of an Effilight® traction transformer which include up to 20 % weight reduction and up to 50% energy savings for customers.

The Natural Cooling Effilight® Traction Transformer will further enable sustainable mobility by making railways more energy efficient and cost-effective.

RESIBLOC® Rail 25 kV

With more than 40 years of leadership in developing RESIBLOC® dry-type distribution transformers, Hitachi ABB Power Grids has successfully brought this safe and trusted technology to the world of traction propulsion systems by introducing RESIBLOC ® Rail. After the successful launch of Resibloc Rail in 2012 with 6.5 kV and with Resibloc® Rail 15 kV in 2018, Hitachi ABB Power Grids has upscaled this technology to now offer RESIBLOC ® Rail up to 25 kV.

Apart from their incredible strength, durability, and high performance, RESIBLOC ® Rail ensures complete protection of people, property, and the surrounding environment by replacing mineral oil with dry insulation material, eliminating risk of oil leakage.

This transformer can perform at nearly maintenance-free operation levels and with up to 45% reduced winding losses at the same weight as traditional units.

With an efficiency of up to 99% RESIBLOC ® Rail traction transformers can reduce operating energy costs and associated carbon emissions of trains by up to 10 percent. This is a decisive advantage for rail operators since energy cost accounts for up to 40% of the total cost in this industry.

Even after the end of their long service life, RESIBLOC ® Rail transformers still show an improved ecological balance as they do not contain any hazardous substances. This makes it possible to easily recycle these transformers.

With rail passenger and freight transport expected to double by 2050, energy consumption, CO2 emissions and atmospheric pollutants would also increase. Electrified rail can lower transport energy usage as well as reduce carbon dioxide and local pollutant emissions. As an essential element in rail electrification, energy-efficient and highly reliable traction transformers like RESIBLOC ® Rail 25 kV & Natural Cooling Effilight ® Traction Transformer will play key role in shaping the sustainable mobility of the future.